Looking for the perfect demolition tool? Look no further than our range of Hydraulic Hammers for

Excavators. These powerful tools are designed to break through tough materials with ease, making

them ideal for a variety of demolition projects. Whether you're working on a big demolition job or

tackling a smaller renovation, TocDem Hydraulic Hammers are up to the task.

With their reliable performance and durability, you can trust TocDem excavator hammers will get the

job done efficiently and effectively. Our Hydraulic Hammers are versatile, easy to use, and built to

last, making them a must-have tool for any demolition project. So why settle for anything less than

the best? Choose TocDem for your Hydraulic Hammers and experience the difference for yourself.

More About Our Hydraulic Hammers

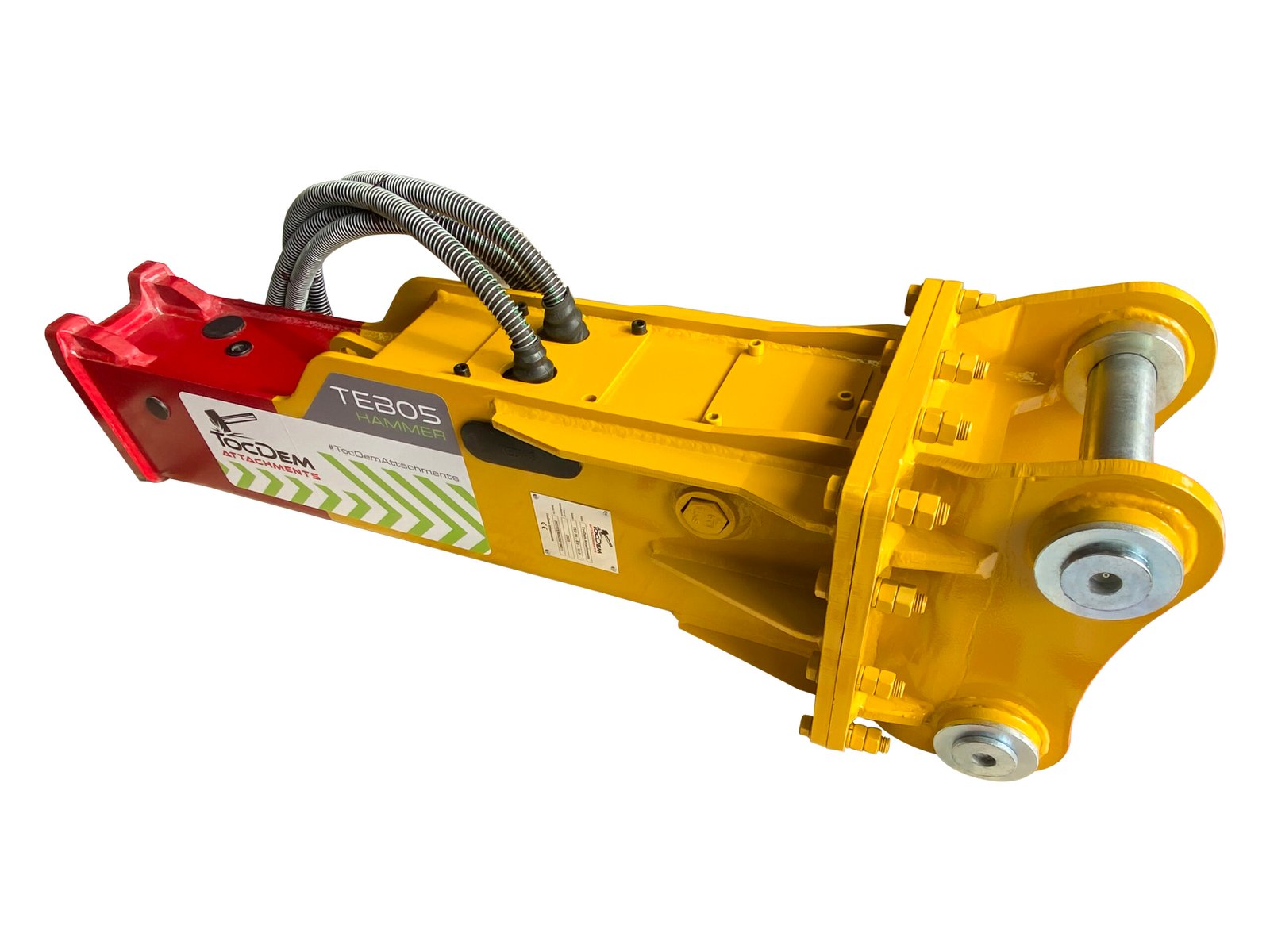

TocDem hydraulic hammers also known as a concrete excavator rock breaker or pecker are

engineered to maximise power and efficiency on your toughest job sites. Utilising cutting-edge

technology and built to the highest specifications, they will deliver exceptional performance in

demolition, mining, construction, ground excavation, and utility applications.

CLICK TO CALL FOR HELP & INFORMATION. WE

WON'T BE BEATEN ON PRICE, QUALITY OR AFTER SALES SERVICE!

CLICK HERE TO

SEE OUR STOCK INCLUDING HYDRAULIC HAMMERS

Our hydraulic hammer models are designed to be compatible with various sizes of excavators, starting

from the smaller 0.8 ton excavators all the way up to the larger 55 ton excavators. This means that

whether you have a compact mini-excavator for light-duty tasks or a heavy-duty excavator for more

demanding jobs, there is a hydraulic hammer option available for you.

When operating a hydraulic hammer attachment on an excavator, it's important to understand the

basics. The hydraulic rock breaker is powered by the hydraulic system of the excavator, utilising

the machine's hydraulic pressure to deliver powerful blows. This makes it an efficient and effective

tool for breaking through tough surfaces like concrete, rock, or asphalt.

One key factor to consider when using a hydraulic hammer is the carrier weight of your excavator.

Different hydraulic hammer models are suitable for different carrier weights, ensuring optimal

performance and safety during operation. It's crucial to match the hydraulic hammer to the

appropriate carrier weight to prevent damage to both the attachment and the excavator. Additionally,

proper maintenance and care are essential for prolonging the lifespan of your hydraulic hammer.

Regularly checking for wear and tear, monitoring hydraulic fluid levels, and following manufacturer

guidelines for operation and maintenance can help ensure that your hydraulic hammer remains in top

condition for years to come.

Key Benefits:

- Excellent Impact Rate: With one of our concrete breakers you can get the job done faster

with their deep, severe impacts and high blows per minute (BPM).

- Wide Energy Range: Choose from models ranging from 121 ft-lb to 12,000 ft-lb to match

your project needs.

- Quality & Reliability: Each pecker undergoes rigorous testing before delivery, and we

continuously research new techniques to improve our products.

- Comprehensive Support: With all TocDem excavator attachments we offer technical

advice, full stock of spare parts.

A key feature of TocDem attachments is always “standing behind” and supporting any product we sell,

we always stock a full range of all spares for TocDem Hammers available for immediate delivery and

are always available to give technical advice & support on the range.

Included With Every Product:

All TEB TocDem Utility & Demolition Hydraulic Hammer attachments are priced complete & ready for use.

- Head brackets/hangers

- Couplings and hoses

- 2 points/chisels

- Spares and toolbox

TocDem Hydraulic Hammers in stock:

Every TocDem Hydraulic Hammer comes with TWO YEARS WARRANTY

Why not contact us today for pricing and

information on our complete range of hydraulic hammers for excavators.

We won't be beaten on

price, quality, or after-sales service!

**Due to ongoing development, specifications may change at any time

These tools should only EVER be operated by trained, qualified

personnel. A valid risk assessment & method statement should always be in place before use. The

Excavator powering this item should always be fitted with a cab & Demolition guards.