Introduction

The construction and demolition industry is undergoing a transformation. With sustainability targets becoming stricter and the circular economy gaining ground, contractors and recycling professionals are expected to do more than simply complete the job. They are asked to minimise waste, maximise resource recovery and operate in a way that reduces environmental impact.

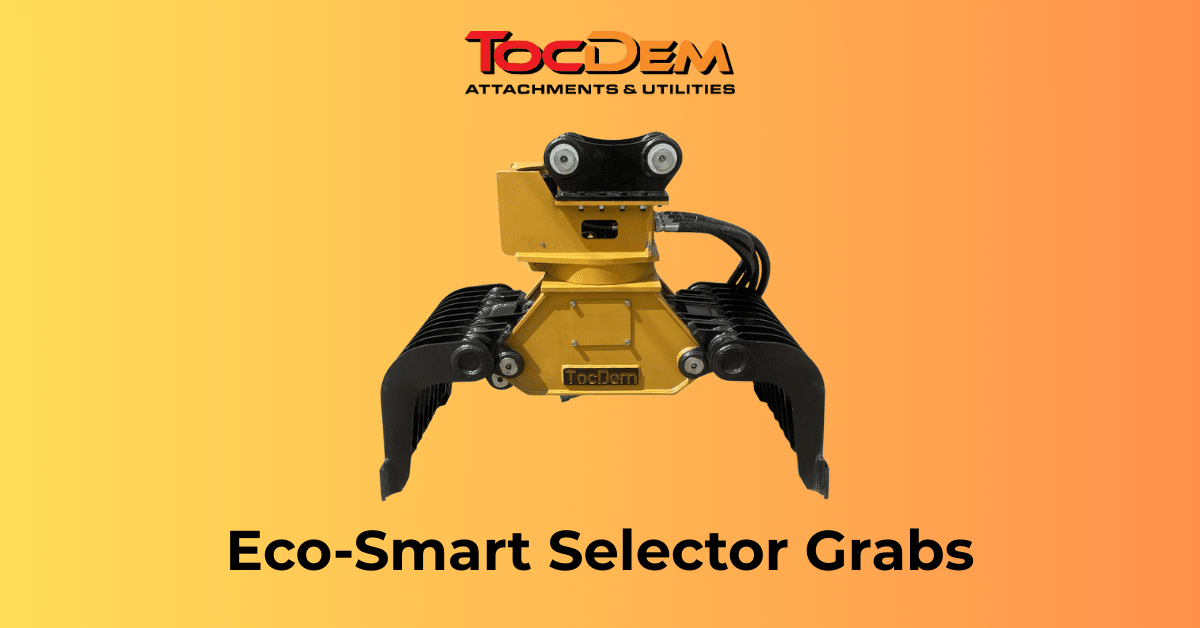

Amidst this shift, one tool is quietly proving its value: the selector grab. These versatile attachments are not only boosting efficiency on demolition sites but also making recycling more practical and profitable. At TocDem Attachments & Utilities, we have seen first-hand how our TGR Selector Grabs are helping contractors, recyclers and plant hire firms meet the new demands of a green economy.

Why Selector Grabs Are Essential for Eco-Smart Operations

Selector grabs were once considered a convenience tool for demolition and scrap yards. Today, they are becoming a necessity. Their ability to sort and handle material with precision directly supports eco-friendly practices.

Efficient sorting with minimal waste

- Grabs can separate materials such as timber, metal and masonry at the point of demolition.

- Clean sorting reduces the volume of waste sent to landfill and lowers processing costs.

- Recyclable material is easier to recover and resell, creating extra revenue streams.

Reduced fuel use and machine wear

- Unlike bulk buckets or clamshells, selector grabs move material with greater accuracy.

- Less repositioning means fewer excavator movements, reduced fuel consumption and lower carbon emissions.

- Reduced strain on the excavator extends the machine’s life, contributing to sustainability.

Durable and repairable by design

- Modern grabs are built from high-grade steels and use replaceable wear parts.

- Instead of discarding an entire unit when one part wears out, operators can replace only the worn section.

- This design philosophy aligns perfectly with the principles of sustainability.

Industry Momentum and Market Growth

Selector grabs are no longer niche tools. The global market is expanding rapidly, with projections estimating that the sector will more than double in value over the next decade. This growth is fuelled by:

- Urbanisation: As more projects take place in densely populated areas, precision tools are preferred over bulk handling methods.

- Recycling demand: Governments and councils are pushing for higher recycling rates in construction and demolition waste.

- Environmental regulations: Tighter rules on waste handling, emissions and landfill disposal mean contractors must adapt their equipment.

- Efficiency pressures: Margins are tighter than ever, and tools that save time and fuel are being prioritised.

Selector grabs sit at the intersection of all these factors, making them one of the most relevant tools for the future of demolition and recycling.

TocDem’s TGR Selector Grabs: Built for Green Performance

Not all grabs are created equal. TocDem’s TGR Selector Grabs are engineered with sustainability, efficiency and durability in mind.

Key features include:

- Precision gripping: Our TGR grabs allow contractors to pick and place materials with accuracy, reducing contamination between waste streams.

- Robust construction: Heavy-duty build with wear-resistant pins and plates, ensuring a long lifespan.

- Replaceable parts: Key wear sections can be swapped out quickly, reducing downtime and unnecessary waste.

- Versatility: Suitable for excavators of different sizes, making them useful for demolition sites, recycling yards and even landscaping projects.

- Operator control: Smooth hydraulics and 360° rotation (on select models) improve safety and efficiency on complex tasks.

These design features mean that when contractors choose TocDem’s grabs, they are not just investing in a tool. They are investing in a solution that aligns with modern expectations of safety, compliance and environmental responsibility.

Real-World Applications of Selector Grabs

Selector grabs are proving their worth across a variety of sectors. Here are some examples of where they deliver the strongest impact:

Urban demolition

- Demolition in city centres requires fast, clean and safe handling of materials.

- Selector grabs allow operators to dismantle and separate materials as they go, keeping sites tidy and compliant with recycling targets.

Recycling yards

- At material recovery facilities, precision sorting improves efficiency.

- Grabs help separate ferrous and non-ferrous metals, timber and inert waste with speed and accuracy.

Landscaping and clearance

- Beyond demolition, grabs are also used in landscaping and site clearance.

- They can remove debris without disturbing the ground excessively, reducing environmental impact on sensitive areas.

Plant hire fleets

- For hire companies, grabs are a multi-purpose attachment that clients can use across demolition, recycling and clearance projects.

- Offering TGR Selector Grabs increases the appeal of a hire fleet to contractors focused on efficiency and sustainability.

The Buyer’s Checklist: Choosing the Right Grab

Contractors, recyclers and hire firms considering an investment in selector grabs should evaluate:

- Sorting efficiency: Does the grab deliver precise handling across different material types?

- Durability: Are high-wear components built from quality steel?

- Repairability: Can wear parts be replaced without discarding the entire unit?

- Compatibility: Will it fit a range of excavator sizes?

- Support: Does the supplier provide spare parts, servicing and aftersales assistance?

TocDem’s TGR Selector Grabs tick all these boxes, making them a reliable long-term choice.

Common Mistakes to Avoid

While selector grabs are versatile, mistakes in selection and use can reduce their benefits. Common pitfalls include:

- Using the wrong size grab: A grab too small slows down work, while one too large can overload the excavator.

- Neglecting maintenance: Even durable tools require regular greasing and inspection to avoid downtime.

- Overlooking operator training: Precision handling relies on skilled use. Proper training ensures efficiency and safety.

- Buying only on price: The cheapest option may lack durability, leading to higher costs over time.

Why Contractors Choose TocDem

Contractors and hire companies across the UK trust TocDem because we do more than sell attachments. We provide:

- A range of grabs engineered for modern demolition and recycling

- Expert advice on matching the right grab to the right machine

- Options to buy or hire, giving flexibility to contractors and hire firms

- Reliable aftersales support and spare parts to keep equipment working harder for longer

With TocDem, clients know they are getting more than a product. They are getting a partner committed to their success.

Do not let the wrong tool slow you down. Explore TocDem’s full range of TGR Selector Grabs

Final Word

Selector grabs are no longer optional extras. In today’s construction, demolition and recycling sectors, they are essential for meeting the combined demands of efficiency, compliance and sustainability.

By reducing waste, saving fuel and improving precision, they allow contractors to deliver projects that are not only profitable but also environmentally responsible. TocDem’s TGR Selector Grabs embody these values, combining durability with eco-friendly design and operator-focused performance.

The future of demolition and recycling is greener, and selector grabs are leading the way.

Find out how TocDem’s TGR Selector Grabs can transform your next project.