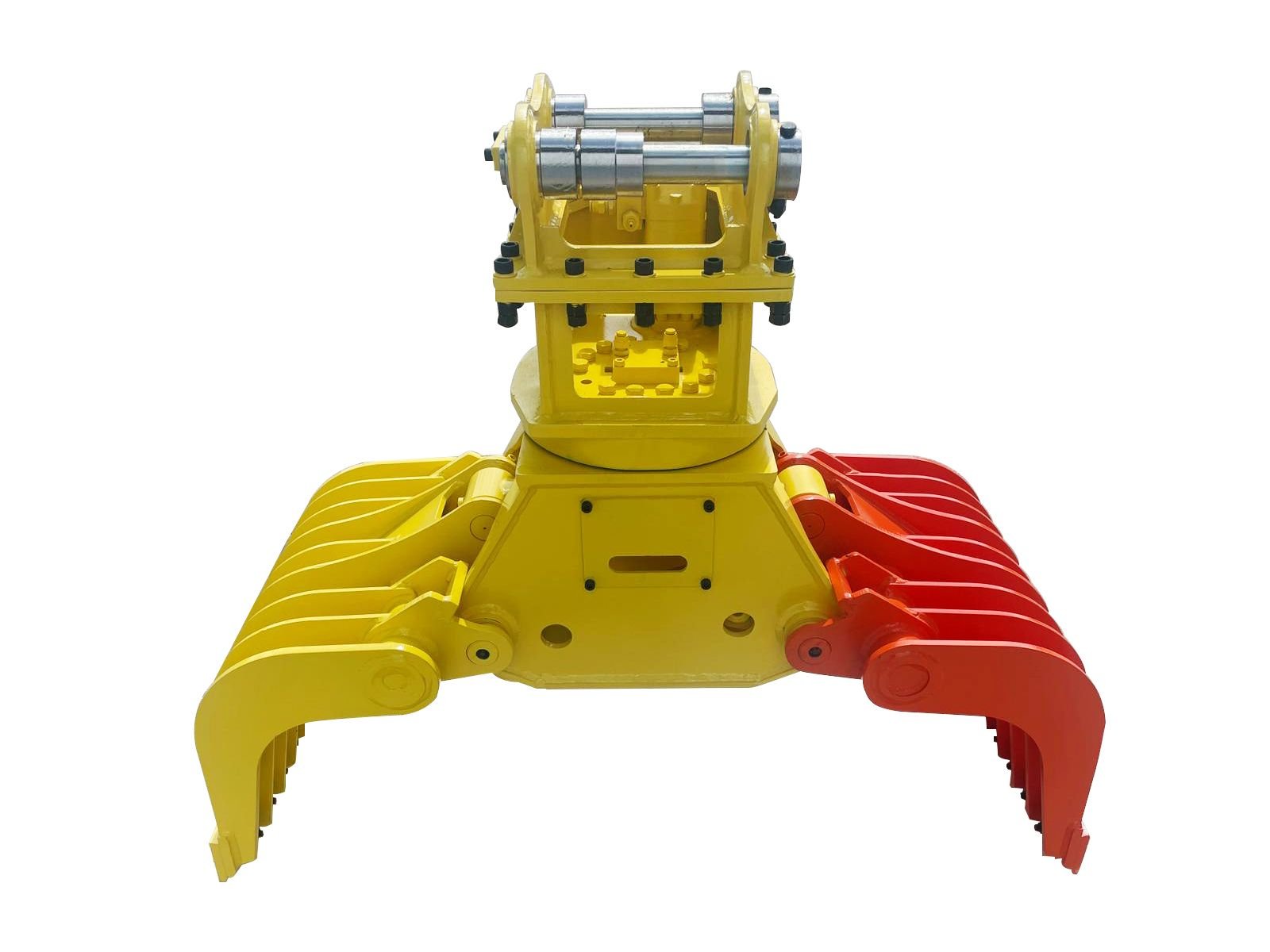

TGR SERIES Hydraulic Selector GrabsGrapples For Excavators

| Make | TocDem |

| Model | TGR1-S |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR1 |

£2,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR2 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR2 |

£3,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR4 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR4 |

£5,450.00 + VAT

More Details

| Make | TocDem |

| Model | TGR5 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR5 |

£6,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR6 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR6 |

£7,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR12 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR12 |

£11,750.00 + VAT

More Details

| Make | TocDem |

| Model | TGR16 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR16 |

£16,250.00 + VAT

More Details

| Make | TocDem |

| Model | TGR22 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR22 |

£22,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR26 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR26 |

£26,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR32 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR32 |

£29,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR42 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR42 |

£34,950.00 + VAT

More Details| TGR Model | U.M. | TGR 1-S | TGR 2 | TGR 4 | TGR 5 | TGR 6 | TGR 12 |

|---|---|---|---|---|---|---|---|

| PRICE + VAT (GBP) | £2,950 | £3,950 | £5,450 | £6,500 | £7,500 | £11,750 | |

| FULL DETAILS | |||||||

| OPENING (A) | mm | 770 | 770 | 800 | 1,300 | 1,500 | 1,700 |

| in | 31 | 31 | 32 | 52 | 60 | 68 | |

| HEIGHT (B) | mm | 630 | 890 | 905 | 1,140 | 1,275 | 1,600 |

| in | 25 | 35 | 36 | 46 | 51 | 64 | |

| SHELL WIDTH (C) | mm | 350 | 350 | 450 | 550 | 650 | 800 |

| in | 14 | 14 | 18 | 22 | 26 | 32 | |

| EXCAVATOR WEIGHT |

Tonne | 0.8 - 1.9 | 0.8 - 1.9 | 2.0 - 4.0 | 4.0 - 7.0 | 8.0 - 10.0 | 11.0 - 18.0 |

| lbs | 1,760 - 4,180 | 1,760 - 4,180 | 4,400 - 8,800 | 8,800 - 15,400 | 17,600 - 22,000 | 24,200 - 39,600 | |

| ITEM WEIGHT |

Kg | 100 | 140 | 170 | 432 | 619 | 1,040 |

| lbs | 220 | 308 | 374 | 950 | 1,361 | 2,293 | |

| MAX OIL PRESSURE | Bar | 250 | 250 | 250 | 250 | 250 | 250 |

| Psi | 3,626 | 3,626 | 3,626 | 3,626 | 3.626 | 3,626 | |

| OIL CAPACITY | L/min | 15 | 15 | 20 | 20 | 25 | 50 |

| g/min | 3.2 | 3.2 | 4.3 | 4.3 | 6 | 13 | |

| ROTATION OIL PRESSURE |

Bar | NA STATIC | 60 | 60 | 60 | 60 | 140 |

| Psi | NA STATIC | 870 | 870 | 870 | 870 | 2,030 | |

| ROTATION OIL CAPACITY |

L/min | NA STATIC | 20 | 20 | 20 | 20 | 30 |

| g/min | NA STATIC | 4.3 | 4.3 | 4.3 | 4.3 | 8 | |

| LOADING CAPACITY |

Tonne | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 1.1 |

| lbs | 660 | 660 | 660 | 880 | 880 | 2,420 | |

| CLAMPING FORCE |

Tonne | 2 | 2 | 2 | 2 | 2 | 5 |

| lbs | 4,400 | 4,400 | 4,400 | 4,400 | 4,400 | 11,000 |

| TGR Model | U.M. | TGR 16 | TGR 22 | TGR 26 | TGR 32 | TGR 42 |

|---|---|---|---|---|---|---|

| PRICE + VAT (GBP) | £16,250 | £22,950 | £26,500 | £29,500 | £34,950 | |

| FULL DETAILS | ||||||

| OPENING (A) | mm | 1,900 | 2,280 | 2,450 | 2,500 | 3,000 |

| in | 76 | 90 | 96 | 98 | 118 | |

| HEIGHT (B) | mm | 1,760 | 1,800 | 2,000 | 2,100 | 2,300 |

| in | 70 | 72 | 80 | 84 | 92 | |

| SHELL WIDTH (C) | mm | 1,000 | 1,200 | 1,400 | 1,500 | 1,500 |

| in | 40 | 47 | 55 | 59 | 59 | |

| EXCAVATOR WEIGHT |

Tonne | 18.0 / 25.0 | 22.0 / 30.0 | 30.0 / 50.0 | 35.0 / 60.0 | 50.0 / 65.0 |

| lbs | 39,600 / 55,400 | 48,400 / 66,000 | 66,000 / 110,000 | 77,000 / 132,000 | 110,000 / 143,000 | |

| EQUIPMENT WEIGHT | Kg | 1,200 | 1,780 | 2,450 | 2,800 | 3,500 |

| lbs | 2,640 | 3,924 | 5,401 | 6,173 | 7,716 | |

| MAX OIL PRESSURE | Bar | 300 | 300 | 300 | 300 | 330 |

| Psi | 4,351 | 4,351 | 4,351 | 4,351 | 4,786 | |

| OIL CAPACITY | L/min | 50 | 50 | 50 | 120 | 150 |

| g/min | 13 | 13 | 13 | 32 | 40 | |

| ROTATION OIL PRESSURE | Bar | 140 | 140 | 140 | 140 | 140 |

| Psi | 2,030 | 2,030 | 2,030 | 2,030 | 2,030 | |

| ROTATION OIL CAPACITY | L/min | 30 | 30 | 30 | 30 | 30 |

| g/min | 8 | 8 | 8 | 8 | 8 | |

| LOADING CAPACITY | Tonne | 1.5 | 2 | 2.7 | 3.1 | 4 |

| lbs | 3,300 | 4,400 | 5,940 | 6,820 | 8,800 | |

| CLAMPING FORCE | Tonne | 5.7 | 8 | 10.5 | 11.5 | 15 |

| lbs | 12,540 | 17,600 | 23,100 | 25,300 | 33,000 |

**Due to ongoing development, specifications may change at any time

Need a versatile tool for demolition and material handling? Our TGR Series Hydraulic Selector Grabs are the answer. Designed for precision and power, these grapples excel at sorting and handling various materials. With 360-degree rotation and interchangeable blades, they're adaptable to any job. Experience the TocDem difference in efficiency and durability.

TocDem Hydraulic Demolition Grapples are designed to provide efficient and precise handling of various materials. With their hydraulic operation, these grapples offer powerful gripping capabilities, making them ideal for tasks that require strength and control.

Built to withstand tough working conditions, ensuring durability and reliability on the job. Whether you are working in construction, demolition, or forestry, these hydraulic demolition grapples can help streamline your operations and increase productivity.

The TocDem TGR 360-degree rotating demolition and scrap recycling hydraulic selector grabs are your ideal solution for efficient material handling. Constructed from wear-resistant steel, these versatile grabs excel at demolishing brick structures, timber, and other materials.

The design of our machines favours the selection of materials deriving from Demolition & Scrap Recycling in order to facilitate recycling and handling. Suitable for up to 65-tonne excavators.

TocDem Hydraulic Sorting Grapples offer numerous benefits in various industries. One of the key advantages is their ability to handle a wide range of materials, including bulky items, scrap metal, and construction debris. This versatility makes selector grabs a valuable tool for demolition, recycling, and construction projects.

Additionally, selector grabs can improve efficiency by allowing operators to quickly and accurately pick up and move materials without the need for manual labour. This not only saves time but also reduces the risk of injury to workers.

Another benefit of selector grabs is their precision and control, which enables operators to place materials exactly where they are needed. This level of accuracy can help to minimise waste and optimise the use of resources on job sites. Overall, the benefits of selector grabs make them a valuable asset for businesses looking to improve productivity and streamline their operations.

Like all excavator attachments, our scrap recycling hydraulic selector grabs are built to last and come fully equipped, ensuring you get the job done right. Contact us today to explore our range and find the perfect grab for your needs.

Every TocDem SELECTOR GRAPPLE comes with a huge THREE YEARS WARRANTY.

**Due to ongoing development, specifications may change at any time

Need a versatile tool for demolition and material handling? Our TGR Series Hydraulic Selector Grabs are the answer. Designed for precision and power, these grapples excel at sorting and handling various materials. With 360-degree rotation and interchangeable blades, they're adaptable to any job. Experience the TocDem difference in efficiency and durability.

TocDem Hydraulic Demolition Grapples are designed to provide efficient and precise handling of various materials. With their hydraulic operation, these grapples offer powerful gripping capabilities, making them ideal for tasks that require strength and control.

Built to withstand tough working conditions, ensuring durability and reliability on the job. Whether you are working in construction, demolition, or forestry, these hydraulic demolition grapples can help streamline your operations and increase productivity.

| Make | TocDem |

| Model | TGR1-S |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR1 |

£2,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR2 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR2 |

£3,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR4 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR4 |

£5,450.00 + VAT

More Details

| Make | TocDem |

| Model | TGR5 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR5 |

£6,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR6 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR6 |

£7,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR12 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR12 |

£11,750.00 + VAT

More Details

| Make | TocDem |

| Model | TGR16 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR16 |

£16,250.00 + VAT

More Details

| Make | TocDem |

| Model | TGR22 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR22 |

£22,950.00 + VAT

More Details

| Make | TocDem |

| Model | TGR26 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR26 |

£26,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR32 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR32 |

£29,500.00 + VAT

More Details

| Make | TocDem |

| Model | TGR42 |

| Year | 2026 |

| Hours | 0 |

| Stock No | TGR42 |

£34,950.00 + VAT

More Details| TGR Model | U.M. | TGR 1-S | TGR 2 | TGR 4 | TGR 5 | TGR 6 | TGR 12 |

|---|---|---|---|---|---|---|---|

| PRICE + VAT (GBP) | £2,950 | £3,950 | £5,450 | £6,500 | £7,500 | £11,750 | |

| OPENING (A) | mm | 770 | 770 | 800 | 1,300 | 1,500 | 1,700 |

| in | 31 | 31 | 32 | 52 | 60 | 68 | |

| HEIGHT (B) | mm | 630 | 890 | 905 | 1,140 | 1,275 | 1,600 |

| in | 25 | 35 | 36 | 46 | 51 | 64 | |

| SHELL WIDTH (C) | mm | 350 | 350 | 450 | 550 | 650 | 800 |

| in | 14 | 14 | 18 | 22 | 26 | 32 | |

| EXCAVATOR WEIGHT |

Tonne | 0.8 - 1.9 | 0.8 - 1.9 | 2.0 - 4.0 | 4.0 - 7.0 | 8.0 - 10.0 | 11.0 - 18.0 |

| lbs | 1,760 - 4,180 | 1,760 - 4,180 | 4,400 - 8,800 | 8,800 - 15,400 | 17,600 - 22,000 | 24,200 - 39,600 | |

| ITEM WEIGHT |

Kg | 100 | 140 | 170 | 432 | 619 | 1,040 |

| lbs | 220 | 308 | 374 | 950 | 1,361 | 2,293 | |

| MAX OIL PRESSURE | Bar | 250 | 250 | 250 | 250 | 250 | 250 |

| Psi | 3,626 | 3,626 | 3,626 | 3,626 | 3.626 | 3,626 | |

| OIL CAPACITY | L/min | 15 | 15 | 20 | 20 | 25 | 50 |

| g/min | 3.2 | 3.2 | 4.3 | 4.3 | 6 | 13 | |

| ROTATION OIL PRESSURE |

Bar | NA STATIC | 60 | 60 | 60 | 60 | 140 |

| Psi | NA STATIC | 870 | 870 | 870 | 870 | 2,030 | |

| ROTATION OIL CAPACITY |

L/min | NA STATIC | 20 | 20 | 20 | 20 | 30 |

| g/min | NA STATIC | 4.3 | 4.3 | 4.3 | 4.3 | 8 | |

| LOADING CAPACITY |

Tonne | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 1.1 |

| lbs | 660 | 660 | 660 | 880 | 880 | 2,420 | |

| CLAMPING FORCE |

Tonne | 2 | 2 | 2 | 2 | 2 | 5 |

| lbs | 4,400 | 4,400 | 4,400 | 4,400 | 4,400 | 11,000 |

| TGR Model | U.M. | TGR 16 | TGR 22 | TGR 26 | TGR 32 | TGR 42 |

|---|---|---|---|---|---|---|

| PRICE + VAT (GBP) | £16,250 | £22,950 | £26,500 | £29,500 | £34,950 | |

| OPENING (A) | mm | 1,900 | 2,280 | 2,450 | 2,500 | 3,000 |

| in | 76 | 90 | 96 | 98 | 118 | |

| HEIGHT (B) | mm | 1,760 | 1,800 | 2,000 | 2,100 | 2,300 |

| in | 70 | 72 | 80 | 84 | 92 | |

| SHELL WIDTH (C) | mm | 1,000 | 1,200 | 1,400 | 1,500 | 1,500 |

| in | 40 | 47 | 55 | 59 | 59 | |

| EXCAVATOR WEIGHT |

Tonne | 18.0 / 25.0 | 22.0 / 30.0 | 30.0 / 50.0 | 35.0 / 60.0 | 50.0 / 65.0 |

| lbs | 39,600 / 55,400 | 48,400 / 66,000 | 66,000 / 110,000 | 77,000 / 132,000 | 110,000 / 143,000 | |

| EQUIPMENT WEIGHT | Kg | 1,200 | 1,780 | 2,450 | 2,800 | 3,500 |

| lbs | 2,640 | 3,924 | 5,401 | 6,173 | 7,716 | |

| MAX OIL PRESSURE | Bar | 300 | 300 | 300 | 300 | 330 |

| Psi | 4,351 | 4,351 | 4,351 | 4,351 | 4,786 | |

| OIL CAPACITY | L/min | 50 | 50 | 50 | 120 | 150 |

| g/min | 13 | 13 | 13 | 32 | 40 | |

| ROTATION OIL PRESSURE | Bar | 140 | 140 | 140 | 140 | 140 |

| Psi | 2,030 | 2,030 | 2,030 | 2,030 | 2,030 | |

| ROTATION OIL CAPACITY | L/min | 30 | 30 | 30 | 30 | 30 |

| g/min | 8 | 8 | 8 | 8 | 8 | |

| LOADING CAPACITY | Tonne | 1.5 | 2 | 2.7 | 3.1 | 4 |

| lbs | 3,300 | 4,400 | 5,940 | 6,820 | 8,800 | |

| CLAMPING FORCE | Tonne | 5.7 | 8 | 10.5 | 11.5 | 15 |

| lbs | 12,540 | 17,600 | 23,100 | 25,300 | 33,000 |

**Due to ongoing development, specifications may change at any time

The TocDem TGR 360-degree rotating demolition and scrap recycling hydraulic selector grabs are your ideal solution for efficient material handling. Constructed from wear-resistant steel, these versatile grabs excel at demolishing brick structures, timber, and other materials.

The design of our machines favours the selection of materials deriving from Demolition & Scrap Recycling in order to facilitate recycling and handling. Suitable for up to 65-tonne excavators.

TocDem Hydraulic Sorting Grapples offer numerous benefits in various industries. One of the key advantages is their ability to handle a wide range of materials, including bulky items, scrap metal, and construction debris. This versatility makes selector grabs a valuable tool for demolition, recycling, and construction projects.

Additionally, selector grabs can improve efficiency by allowing operators to quickly and accurately pick up and move materials without the need for manual labour. This not only saves time but also reduces the risk of injury to workers.

Another benefit of selector grabs is their precision and control, which enables operators to place materials exactly where they are needed. This level of accuracy can help to minimise waste and optimise the use of resources on job sites. Overall, the benefits of selector grabs make them a valuable asset for businesses looking to improve productivity and streamline their operations.

Like all excavator attachments, our scrap recycling hydraulic selector grabs are built to last and come fully equipped, ensuring you get the job done right. Contact us today to explore our range and find the perfect grab for your needs.

Every TocDem SELECTOR GRAPPLE comes with a huge THREE YEARS WARRANTY.

**Due to ongoing development, specifications may change at any time

All Selector Grabs and Grapples are made to order. Once we have received your deposit payment & the specifications of your Digger, so that we can manufacture the head bracket / hanger, we can usually deliver anywhere in the UK within 6 – 8 weeks.

We only accept payment via bank transfer. After placing an order, we will send you an invoice with our bank details.

We offer a full 3 year warranty on all new TRG Selector Grabs. Subject to warranty terms & conditions

Yes, our engineering department can gladly manufacture and supply head brackets/hangers only. We need the “drill pattern”, and the make and model of your breaker along with the make & model of the Excavator you are using it with.

As versatile and efficient as shears and pulverisers undoubtedly are, there is little doubt that with the advent of the selector grab, building reduction techniques and the processing of materials were greatly enhanced. Fitted directly onto the ‘dipper’ arm or via a quick hitch coupler, the jaws work simultaneously off a separate hydraulic circuit operated by a switch or foot pedal in the cab.

The grab has a 360º rotation capability and the whole attachment can be bent upwards or downwards by virtue of the connection to the bucket ram via a universal jointed frame. These attachments are available from many of the major plant and equipment manufacturers for most types and sizes of demolition rig.

Experience has shown that an operator can be very precise in the removal of individual elements from a building or structure. This improves the capability for recycling and reclamation and reduces the need for manual handling. Loading of scrap or waste products is quick and safe due to the flexibility and strength of the jaws.

Cutting edges on selector grabs are made from wear-resistant material and are bolted on. They can generally be rotated for use. The operation of the attachment jaws is based on the static force produced by the hydraulic cylinder of the equipment, and to increase the product's working life particular attention should be paid to correct working methods.

The Selector Grab should always be attached to an excavator of the correct weight, class and capacity of the machine. Refer to the data information plate on the grab and consult the technical specifications in this manual. When in doubt, contact the supplier.

The weight of the grab, increased by the weight of the load being picked up, must never exceed the maximum allowance of lifting power. For further information consult the excavator manual.

It is prohibited for people to be within the rotation range of the machine and grab. Keep in mind that material being lifted that extrudes from the grab will enlarge the rotation range. It is always possible that material can fall out of the excavator’s grab. For this reason, never rotate the machinery above people, machines or vehicles.

Always pick up a long load at its centre of gravity, to prevent the excavator from either rotating or tipping over. It is not permissible to use the grab to hit or pound. Whilst connecting or disconnecting, lubricating or other maintenance work, the grab must be stable and on a flat surface. Before performing lubricating or other maintenance work the engine should always be shut down.

When choosing the right size grapple for your mini excavator, consider these key factors:

At TocDem we recommend the 4 to 9 Tonne Scrap Selector Grapple TGR6 for a midi excavator. That said, always consult the manufacturer specifications for your excavator and the grab you're considering. Many manufacturers also offer attachment matching tools to simplify the process. If you are unsure please do not hesitate to contact our team at TocDem.

An excavator sorting grapple is a versatile digger attachment used in various construction tasks.

Here are some common applications:

Overall, grapples, either for large or mini excavators are essential tools in construction, offering versatility, efficiency, and precision for a wide range of tasks.

Selection

Selection

Demolition

Demolition

Loading

Loading